Many industrial components are created from sheet material, which is available in a range of metals and thicknesses. Sheet metal fabrication techniques such as laser cutting, computer numerical control (CNC) machining, CNC forming, and welding allow manufacturers to turn these sheets into complex precision components.

Many industrial components are created from sheet material, which is available in a range of metals and thicknesses. Sheet metal fabrication techniques such as laser cutting, computer numerical control (CNC) machining, CNC forming, and welding allow manufacturers to turn these sheets into complex precision components.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a broad term for any manufacturing technique that yields a metal component from flattened raw material. Many hot and cold-forming processes fall under this umbrella, including cutting, bending, punching, machining, and welding, as well as associated finishing and assembly methods.

Sheet metal fabrication techniques are highly versatile and are used for products ranging from car parts to consumer electronics. However, the exact metal process used differs from component to component, depending on the materials and component shapes. When you discuss your project with a knowledgeable sheet metal manufacturer like Metal Works of High Point, we can help identify the fabrication techniques best suited to your application.

Advantages of Sheet Metal Fabrication

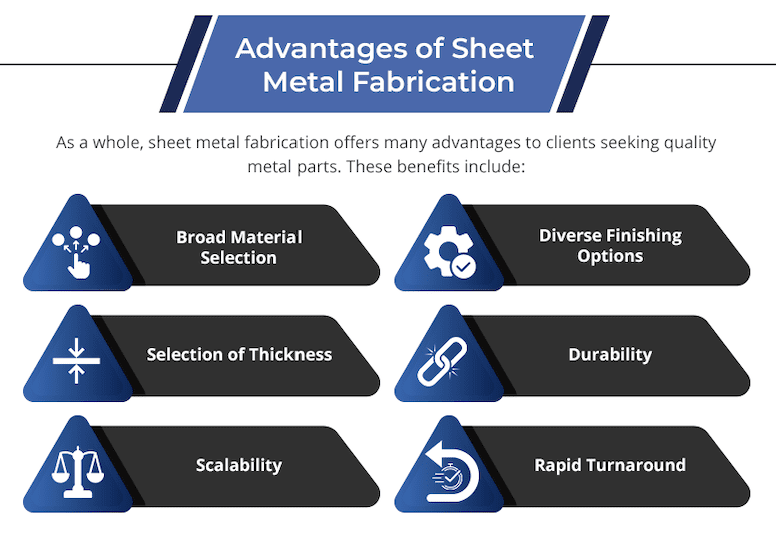

As a whole, sheet metal fabrication offers many advantages to clients seeking quality metal parts. These benefits include:

As a whole, sheet metal fabrication offers many advantages to clients seeking quality metal parts. These benefits include:

- Broad Material Selection: A broad array of metals are suitable for sheet metal fabrication. Whatever the application, we help our clients find a material that offers the desired performance characteristics.

- Diverse Finishing Options: Finishing options such as powder coating, plating, and heat treating can add aesthetic appeal and functional strength to sheet metal parts.

- Selection of Thickness: Sheet metals come in gauges that range from 0.006 to 0.25 in. (0.015 and 0.635 cm.) in thickness. Thick sheet metals accommodate heavy-duty applications, while thinner ones can be formed into complex geometries.

- Durability: Although exact properties depend on the material, most sheet metal products are both strong and highly durable.

- Scalability: Sheet metal fabrication accommodates projects ranging from prototypes to high-volume production runs. Most techniques can be automated, so even the highest volumes can be produced quickly, consistently, and cost-effectively.

- Rapid Turnaround: On the whole, sheet metal fabrication is a rapid process, especially when aided by CNC and automation. We consistently achieve lead times as short as 3 weeks, depending on the component complexity.

In sum, sheet metal fabrication is fast, reliable, and customizable, so it is a good option for a vast array of products.

4 Main Types of Sheet Metal Fabrication Techniques

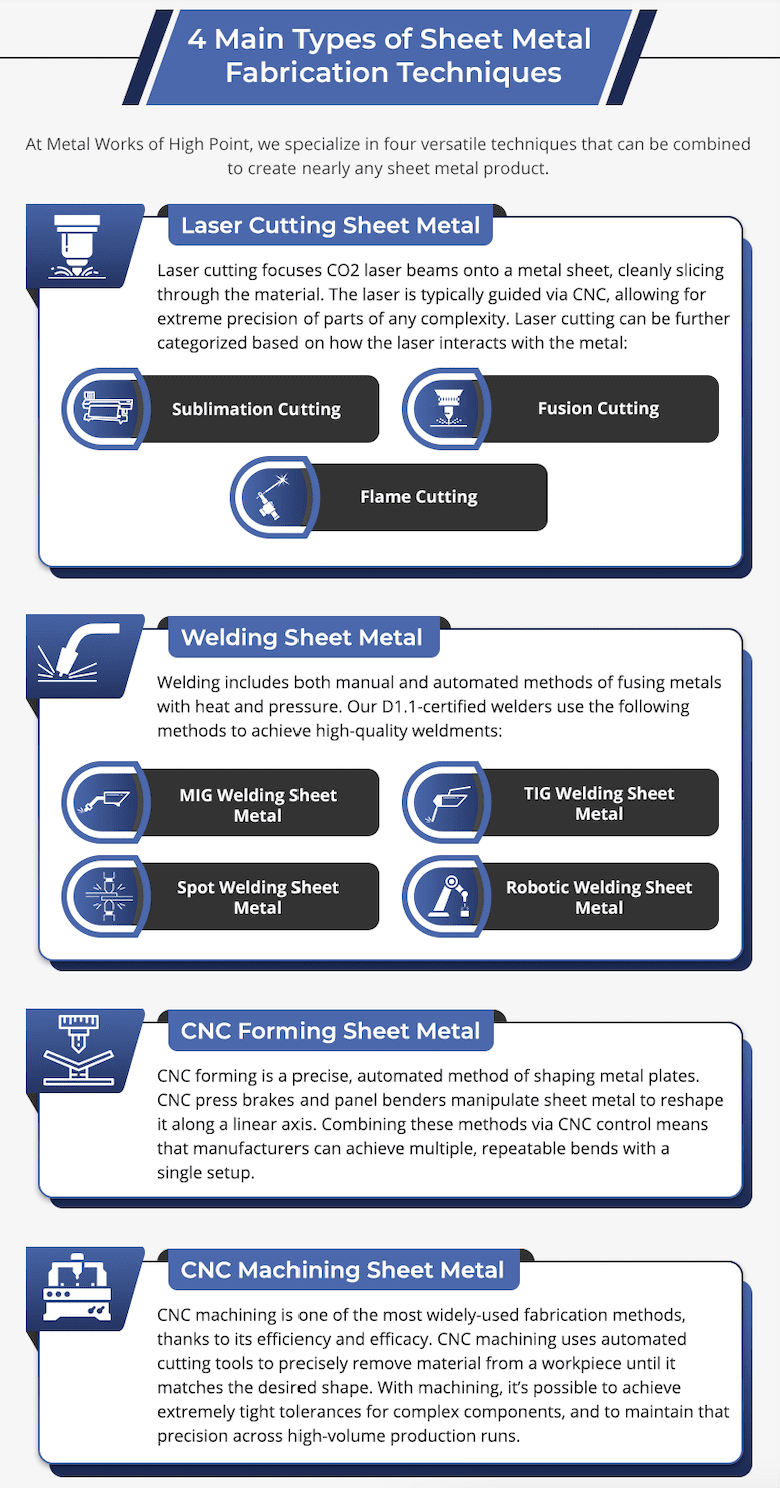

At Metal Works of High Point, we specialize in four versatile techniques that can be combined to create nearly any sheet metal product.

At Metal Works of High Point, we specialize in four versatile techniques that can be combined to create nearly any sheet metal product.

Laser Cutting Sheet Metal

Laser cutting focuses CO2 laser beams onto a metal sheet, cleanly slicing through the material. The laser is typically guided via CNC, allowing for extreme precision of parts of any complexity. Laser cutting can be further categorized based on how the laser interacts with the metal:

- Sublimation Cutting: In sublimation cutting, the laser itself heats the material until it vaporizes. This method is ideal for cutting thin sheets.

- Fusion Cutting: In fusion cutting, the laser heats small regions of the metal until they melt. Then, a pressurized stream of inert gas (typically nitrogen or argon) removes the molten material. This technique is most useful for high-alloy steel and aluminum materials with thicknesses up to 15 mm.

- Flame Cutting: Flame cutting uses a laser plus an assist gas (usually oxygen) to create a flame that cuts the metal. This technique is best used for low-alloy steels up to 25 mm in thickness.

Welding Sheet Metal

Welding includes both manual and automated methods of fusing metals with heat and pressure. Our D1.1-certified welders use the following methods to achieve high-quality weldments:

- MIG Welding Sheet Metal: In metal inert gas or MIG welding, the welder heats a consumable metal wire electrode at the junction of two metal workpieces. The wire and the workpiece melt together, forming a strong bond. This is one of the most popular and versatile welding methods.

- TIG Welding Sheet Metal: Tungsten inert gas or TIG welding is a technically demanding form of welding that uses a non-consumable Tungsten electrode. In this method, the welder creates an arc between the base metal and the electrode, melting the workpiece but not the electrode. TIG welding creates strong welds that can withstand harsh environmental conditions. It is also compatible with non-ferrous metals, which are difficult to weld using other approaches.

- Spot Welding Sheet Metal: During spot welding, sheets are held together under high pressure while the welder applies heat from two copper-alloy electrodes. Spot welding is economical and easily automated. It is best suited to metals with high resistance and moderate to high toughness; metals with low resistance require very high current to generate sufficient heat, and brittle metals may crack under the pressure. Ideal materials include low carbon steel, nickel alloys, and titanium.

- Robotic Welding Sheet Metal: Robotic welding is an advanced technique that uses computer control to automate part handling and welding. Robotic welding helps to maintain consistent results across high-volume runs. It also allows for higher precision than manual welding methods.

CNC Forming Sheet Metal

CNC forming is a precise, automated method of shaping metal plates. CNC press brakes and panel benders manipulate sheet metal to reshape it along a linear axis. Combining these methods via CNC control means that manufacturers can achieve multiple, repeatable bends with a single setup.

CNC Machining Sheet Metal

CNC machining is one of the most widely-used fabrication methods, thanks to its efficiency and efficacy. CNC machining uses automated cutting tools to precisely remove material from a workpiece until it matches the desired shape. With machining, it’s possible to achieve extremely tight tolerances for complex components, and to maintain that precision across high-volume production runs.

Commonly Used Materials

The popularity of sheet metal fabrication is partly due to its versatility. The above techniques can be performed on a wide range of materials, depending on the desired component characteristics. Some of the most popular metals include:

- Steel: Steel is fundamentally an alloy of iron that contains a small amount of carbon to improve its strength. However, different varieties of steel contain dramatically different alloy contents, so the exact properties depend on the grade of steel. In general, steel is strong and durable, yet machinable and formable, so it is one of the most versatile metals in manufacturing.

- Stainless Steel: Stainless steel is a steel alloy that contains at least 11% chromium, which lends the material high corrosion resistance. Stainless steel is used whenever conventional steel might rust. For instance, components that are used outside or subject to frequent sanitization are best made from stainless steel.

- Aluminum: Aluminum is best known for its high strength-to-weight ratio, which makes it popular in aerospace and construction applications. It is corrosion resistant with strong thermal and electrical properties, but it lacks the strength and heat-resistance of stainless steel.

- Brass: Brass is lightweight and corrosion resistant with desirable acoustic properties. Brass alloys are used for varied applications, including musical instruments and plumbing components. Its distinctive appearance and light weight also make it a good choice for decorative applications.

- Bronze: Bronze is a tin-copper alloy that offers greater strength than copper alone. Additional properties include corrosion resistance and a low coefficient of friction, which make bronze a useful material for fittings such as bushings and bearings. Other applications include instruments and nautical or plumbing components.

- Copper: Copper is best known for aging with a distinctive patina that is desirable for decorative applications. It is also highly conductive and ductile, so it is commonly used for electrical components.

The team at Metal Works of High Point can help you identify the best sheet metal for your needs.

Metal Works of High Point Capabilities and Services

At Metal Works of High Point, we have extensive experience working with all of the above processes and metals. In addition, we offer in-house powder coating to protect precision components, and we contract with local partners to offer a broader range of finishing services.

As an ISO 9001:2015-certified facility, all of our sheet metal fabrication services meet the most rigorous quality standards. To learn more about our specific capabilities, contact us or request a quote today.